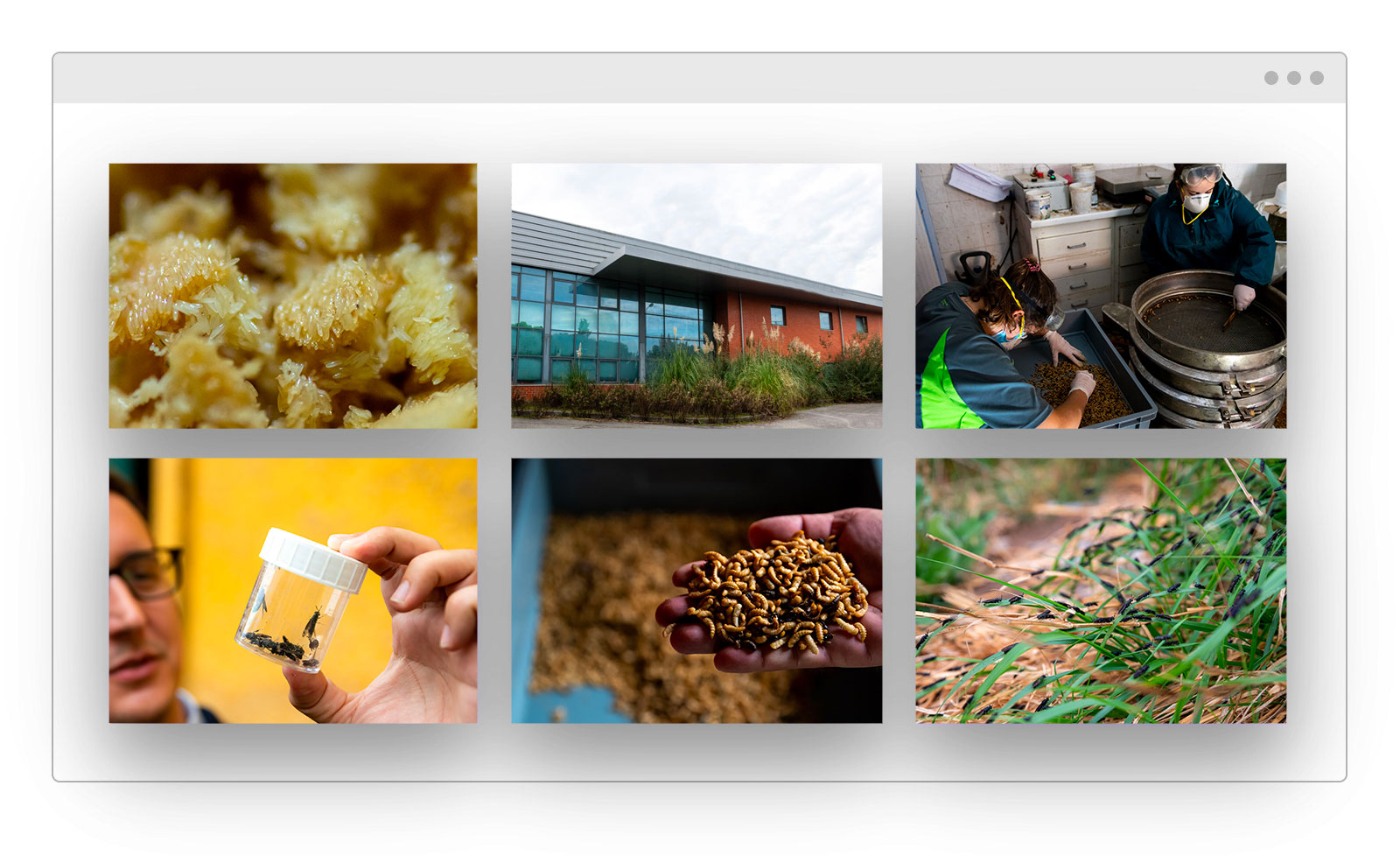

A EntoGreen pretende contribuir para o desenvolvimento de uma alimentação sustentável, centrando-se no desenvolvimento de tecnologias de base biológica que possibilitem reutilizar os desperdícios nutricionais que ocorrem no sector agroalimentar, reintroduzindo-os na cadeia de valor.

Uma pequena introdução

- Entogreen e sua história

- A nossa equipa

- Ingredient Odyssey a empresa mãe

Bioindústria

A EntoGreen desenvolveu um processo de bioconversão de desperdícios vegetais…

Bioconversão

Disponibilizamos um serviço de valorização de desperdícios alimentares de origem vegetal.

Fertilizante Orgânico

Um equilíbrio de azoto, fosforo e potássio que o coloca entre os melhores fertilizantes.

Get Our Tech

Pegada Verde

O nosso compromisso, o seu certificado

A actividade da Entogreen assenta na mudança e no contributo para a sustentabilidade, optimizando a pegada ecológica do sector agro-alimentar.

O Impacto da Entogreen

A farinha de peixe, fonte proteica utilizada na aquacultura é altamente insustentável face à já sob exploração dos oceanos. A proteína de inseto produzida pela Entogreen é um substituto da mesma.

I&D

A génese da Entogreen® e o motor para o estabelecimento de novas metodologias e produtos.

Publicações | Teses | Experiências e Parceiros de Investigação e Desenvolvimento

Projectos

Promovidos pela empresa Ingredient Odyssey, S.A. e pela EntoGreen®, pretendem colaborar neste esforço tendo como objetivo principal contribuir para a transição para uma economia circular no sector agroalimentar, em que o valor dos produtos, materiais e recursos se mantenha na cadeia de valor o máximo de tempo possível e a produção de resíduos se reduza ao mínimo…

![]()

Imprensa & Media

Fique a par de todas as notícias, videos, e redes sociais da Entogreen.